HOME › Forums › General Discussions › Smooth Operation and Noise Reduction: Expert Fan Balancing Services

This topic contains 0 replies, has 1 voice, and was last updated by Balancingrem 3 days, 3 hours ago.

-

AuthorPosts

-

November 9, 2024 at 8:09 pm #736871

<div>

<h1>Generator Balancing: Enhance Performance and Efficiency</h1>

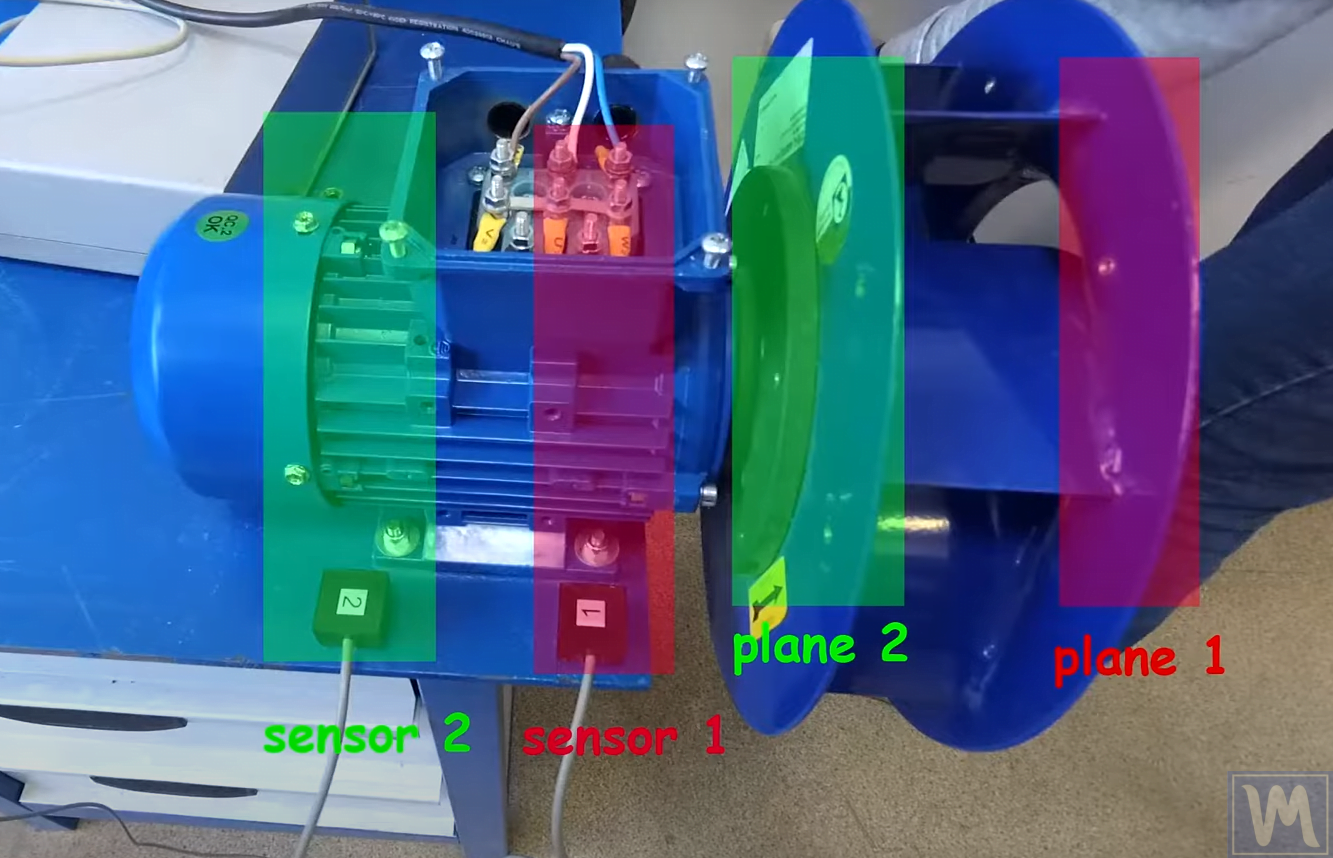

<p>Generator balancing is a crucial process that ensures the smooth operation of various machinery, including generators. At the forefront of this field is the innovative portable balancer and vibration analyzer, “Balanset,” designed to offer dynamic balancing capabilities for a wide range of equipment.</p><p>The “Balanset-1A” is a versatile dynamic balancing instrument equipped with two channels, enabling it to perform balancing in two planes. This capability makes it ideal for a broad spectrum of applications, from crushers to fans, augers, turbines, and more. The adaptability of the Balanset-1A makes it an invaluable tool in various industries where rotor performance is paramount.</p>

<h2>The Importance of Balancing</h2>

<p>Balancing is not just a technical necessity; it’s critical for maintaining the longevity and efficiency of machinery. Imbalances in machinery can lead to excessive vibration, causing wear and tear on components. This is particularly true for generators and similar devices, where any misalignment can ultimately lead to costly breakdowns and unscheduled maintenance. Implementing generator balancing effectively minimizes these risks, ensuring consistent performance and extending the lifespan of the equipment.</p><h2>Dynamic Balancing vs. Static Balancing</h2>

<p>There’s often confusion between static and dynamic balancing. Static balancing addresses the weight distribution of a component at rest, while dynamic balancing involves the assessment and remediation of balance at operational speeds. The Balanset-1A makes this distinction clear by providing tools for accurate measurement and adjustment based on the machine’s operating conditions. This ensures optimum performance during operation, especially in high-demand environments.</p><h2>Advanced Features of Balanset</h2>

<p>The “Balanset-4” model takes balancing to the next level with its four-channel capability, specifically designed for dynamic balancing in four planes. This feature is particularly beneficial for applications involving cardan shafts and other complex rotating systems. The additional measurement channels provide enhanced precision, leading to better outcomes in generator balancing tasks. Users can expect a significant improvement in efficiency, helping reduce operational costs.</p><h2>Ease of Use</h2>

<p>One of the standout features of the Balanset series is its user-friendly design. The devices come equipped with intuitive interfaces that allow users of all skill levels to perform balancing operations efficiently. The Balanset-1A, for instance, offers easy calibration and setup, making it accessible even to those who may not have extensive technical expertise. This accessibility empowers operators to take charge of their machinery’s maintenance and performance proactively.</p><h2>Applications in Various Industries</h2>

<p>Generator balancing has widespread applications across numerous industries. In manufacturing, for instance, balancing reduces the likelihood of unexpected machinery failure, ensuring production lines run smoothly. In the medical field, centrifuges require precise balancing to function effectively. Failure to balance these important devices can lead to inaccurate results and compromised patient care.</p><p>In the agricultural sector, equipment such as augers, fans, and mulchers benefiting from generator balancing adds to the efficiency of operations, ensuring that machinery works optimally in the field, thus maximizing production yield and minimizing downtime.</p>

<h2>Proactive Maintenance with Regular Balancing</h2>

<p>Regular generator balancing is an investment in preventive maintenance. By committing to routine checks and adjustments, organizations can avoid significant costs related to machinery breakdowns, production loss, and emergency repairs. This proactive approach shifts maintenance from a reactive to a planned and structured operation, thus fostering a culture of safety and efficiency within a company.</p><h2>Choosing the Right Equipment</h2>

<p>When it comes to generator balancing, selecting the right equipment is essential. The Balanset series provides various options tailored to different needs, ranging from portable solutions to advanced multi-channel systems. Each device comes with detailed manuals and customer support, ensuring users can maximize their investment while achieving the perfect balance in their operations.</p><h2>Getting Started with Generator Balancing</h2>

<p>If you’re looking to implement balancing solutions within your operations, the first step is to assess the specific requirements of your machinery. Consider factors such as types of equipment, operational conditions, and frequency of use. With this knowledge, you can choose the appropriate Balanset model to achieve optimal generator balancing.</p><h2>Contact Us for More Information</h2>

<p>Your journey towards enhanced performance doesn’t have to be overwhelming. Our team at Vibromera is here to provide guidance and answer any questions you might have regarding generator balancing. We offer comprehensive support, ensuring you harness the full potential of your balancing systems.</p><p>In conclusion, generator balancing is an essential facet of machinery maintenance that can significantly impact operational efficiency. Investing in advanced solutions like the Balanset series not only safeguards equipment but also contributes to a reliable, cost-effective, and productive work environment.</p>

</div>

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://www.youtube.com/@vibromera -

AuthorPosts

You must be logged in to reply to this topic.